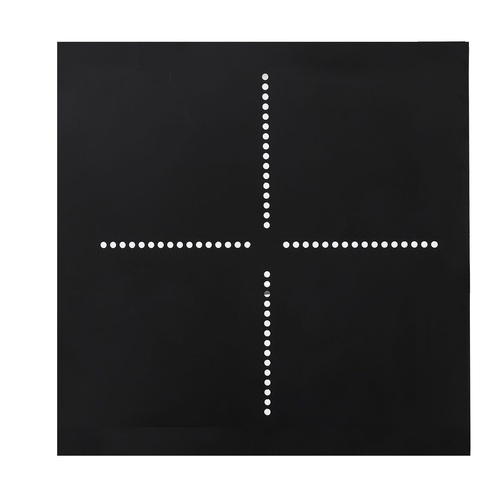

(« Поворотный столик с точностью задания угла до 1° по ГОСТ Р 8.619—2006 »).

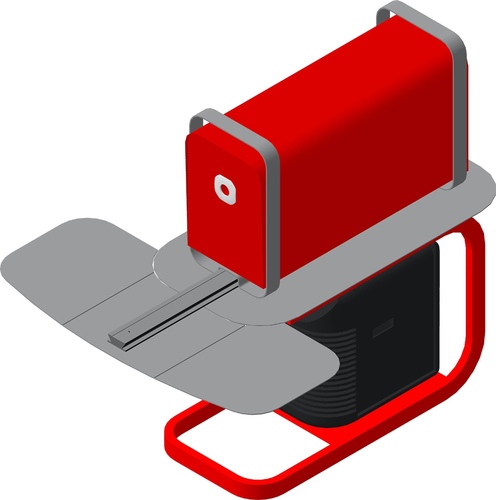

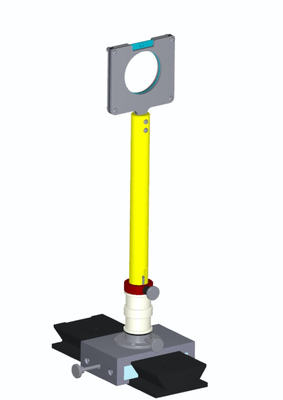

Кроме всех регулировок РЕЙТЕРА ДЛЯ ПИРОМЕТРОВ, имеет возможность зажима прибора за вертикальную рукоятку. Это позволяет механизм наклона зажимных лапок. Также в комплекте имеется площадка для крепления габаритных приборов без рукояти. Отличительной особенностью нового рейтера является наличие лимба отсчета угла поворота с точностью задания угла до 1°C , что является обязательным условием для поверки тепловизоров по ГОСТ Р 8.619—2006, п.4 "Операции и средства поверки". Крепление на Рельс оптический длиной 200 мм.

(в соответствии с ГОСТ Р 8.619—2006) предназначен для определения угла поля зрения тепловизоров.

Отсчет угла поворота вокруг вертикальной оси по лимбу с точностью 1°.

Технические характеристики:

- регулировка по азимуту 360°

- регулировка по углу наклона от +15 до -90°

- регулировка по высоте 30 мм

- расстояние между лапками от 0 до 92 мм

- высота оптической оси с учетом Рельса min 337 … max 367 мм

Габаритные размеры СП (без Рельса) Д х Ш х В, мм: 185 х 120 х 36

Масса 2,5 кг

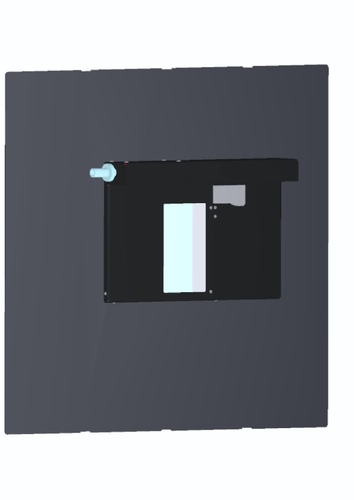

Габаритные размеры Площадки для крепления приборов Д х Ш, мм: 243 х 200

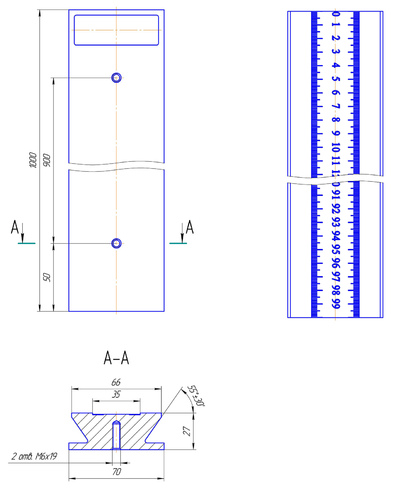

Габаритные размеры Рельса (Д х Ш х В), мм: 200 х 70 х 27

Масса Рельса 200 мм 0,7 кг

Комплектность:

- Стол поворотный– 1 шт.

- Рельс оптический 200 мм – 1 шт.;

- Площадка для установки СИ – 1 шт.;

- Ремень – 1 к-т;

- Крепление – 1 к-т

- Паспорт – 1 экз.

- Тара – 1 к-т

Buy

-min_500x500_bf3.jpg)

-min_500x500_bf3.jpg)

-min_500x500_bf3.jpg)

-min_500x500_bf3.jpg)

-min_500x500_bf3.jpg)

-min_150x150_e1a.jpg)

-min_150x150_e1a.jpg)

-min_150x150_e1a.jpg)

-min_150x150_e1a.jpg)

-min_150x150_e1a.jpg)